Manufacturing Case Studies

Manufacturing Case Studies

Case Study:

Artificial Intelligence: Powering the next phase of Digital Transformation for a Supply Chain Company

Goal:

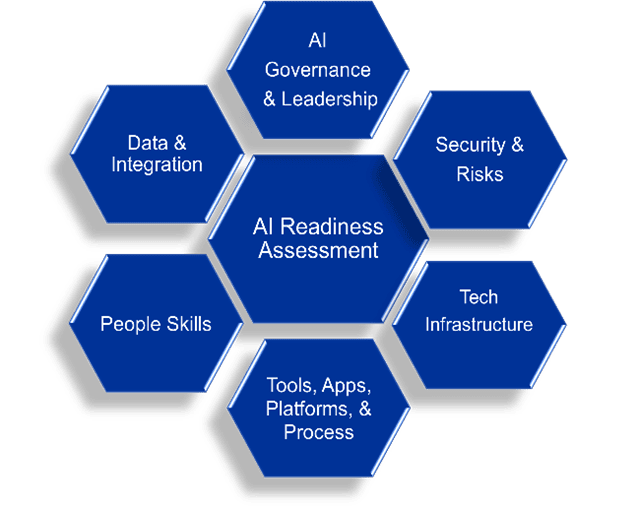

Conduct an AI readiness assessment to develop a tailored AI strategy expanding the next phase of digital transformation.

Solution:

Valulenix worked collaboratively with the company's leadership teams for 2.5 months to assess their current tech ecosystem, AI and data capabilities, technical skills, as well as organizational readiness.

Results:

Valulenix assessment process helped leadership understand AI's vital role in their digital transformation, business strategy, and workforce development. Valulenix created a customized AI strategic roadmap and mission that aligns with the company goals, guides their AI adoption, and manages risks while focused on value creation.

Case Study:

Generative AI (GenAI): Upskilling and using Copilot to enhance workflows and drive productivity gains

Current Situation & Opportunity:

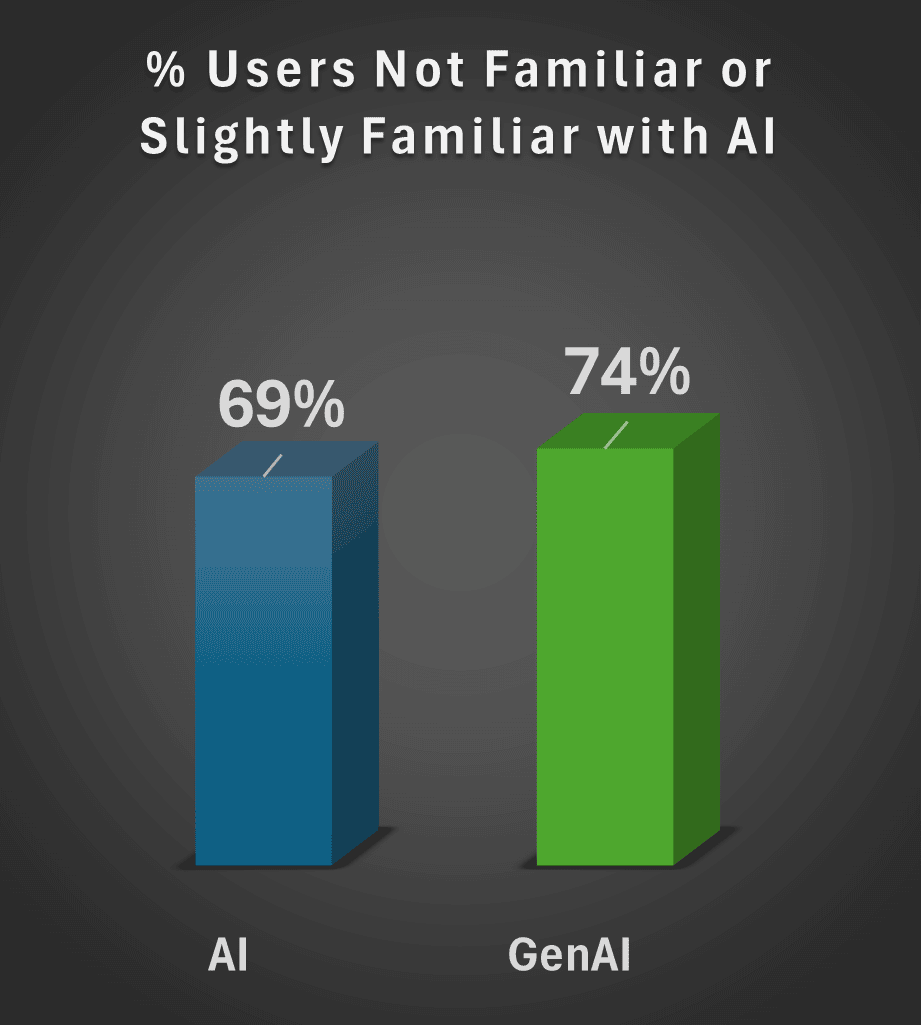

A supply chain and manufacturing client, new to AI and GenAI technology, sought to assess the feasibility and benefits of using GenAI tools for staff and address related data security concerns. Staff and management had little experience with these technologies and were unclear about the impact and value on their daily workflows and tasks.

Solution:

Valulenix ran a 10-week Microsoft Copilot proof of concept with a cross-functional team, focusing on GenAI prompting, Copilot app integration, hands-on activities, and agent development. We assessed user experience, adoption, and productivity, and provided insights for IT to monitor and secure confidential data in Copilot and GenAI models.

Results:

POC participants saw a 43% average productivity increase, with 67% noting positive effects on workflow efficiency. Each saved about 50 minutes weekly, suggesting strong company-wide financial benefits at scale. Also, the POC outperformed some industry benchmarks noted in the table below. With these results, Valulenix helped the client validate the business impact and justify the investment of upskilling staff with GenAI tools.

Case Study:

AI-Driven Process and Product Quality Improvements in Manufacturing

Traditional Approach & Challenge:

To maintain cost leadership, the manufacturer must continuously improve product quality and reduce costs. However, IoT sensors detect temperature changes too late, allowing some defects to persist and affect product quality.

Solution:

One of our consultants implemented a AI solution that predicts temperature variation before it happens and adjust equipment real-time to reduce and avoid process and product defects.

Results:

The AI solution reduced temperature variation by up to 46%, improved product quality, decreased waste, and did not require new capital equipment.

Case Study:

Building AI Core Competency

Opportunity & Challenge:

A mid-size manufacturer set out to make AI a core competency and embed it across operations but lacked the scalable and standardize processes to rapidly meet demand for production ready, AI solutions.

Solution:

A seasoned consultant deployed a comprehensive AI/ML development and QA framework, upskilling over 20 manufacturing engineers and operational SMEs on how to design and implement scalable machine learning solutions.